In the realm of manufacturing, construction, and design, the term ‘cut sheet’ often surfaces, yet its meaning and significance remain elusive to the uninitiated. Cut sheets are essential documents that bridge the gap between conceptual plans and physical reality, serving as detailed guides for the fabrication or installation of products and components. But what exactly constitutes a cut sheet, and why are they so pivotal to professionals in these industries?

In our comprehensive article, “What Are Cut Sheets,” we unravel the layers of this technical tool to provide you with a clear and concise understanding of its function and importance. Our expertise in industry practices ensures that we not only define what cut sheets are but also illuminate their role in the successful execution of projects.

This article is crafted to demonstrate the indispensable value of cut sheets, detailing how they provide critical specifications, measurements, and instructions that are vital for quality control and precision in complex projects. Whether you are an engineer, an architect, a contractor, or someone with a keen interest in the mechanics of project planning and execution, cut sheets are a component of the process you cannot afford to overlook.

With a focus on establishing expertise on the topic, we delve into the intricate details that make cut sheets a linchpin in project planning. Our aim is to pique your curiosity by shedding light on how these documents are created, interpreted, and utilized across various disciplines. We also explore the potential consequences of overlooking this crucial element in the planning phase, emphasizing the need for meticulous attention to detail.

As you begin this article, expect to be drawn into a world where precision is paramount and where cut sheets stand as unsung heroes of project efficiency and success. Join us on this exploratory journey to decode the complexities of cut sheets, and in doing so, gain invaluable insights that could transform the way you approach your next project.

Contents

Introduction

What is a Cut Sheet in Construction?

A cut sheet in construction is a detailed document that provides specifications and technical data for a particular product or material. Cut sheets serve as a vital communication tool between various stakeholders in a construction project, including architects, engineers, contractors, subcontractors, and suppliers.

Definition and Purpose

Simply put, a cut sheet gives all the necessary information required to properly specify, purchase, install, and utilize a product on a project. The purpose of a cut sheet is to clearly convey the exact product characteristics and installation requirements so there is no ambiguity or miscommunication. Having accurate cut sheets helps reduce errors and inefficiencies throughout the construction workflow.

Understanding Cut Sheets

Types of Cut Sheets (e.g., electrical, plumbing, structural)

Cut sheets come in many forms depending on the product category. Some common types include:

- Electrical – For lighting fixtures, switches, wiring, panels, and other electrical components.

- Plumbing – For pipes, valves, fixtures, drains, and other plumbing parts.

- HVAC – For air handling units, ductwork, vents, fans, and other HVAC components.

- Structural – For steel beams, columns, trusses, rebar, and other structural materials.

- Architectural – For doors, windows, hardware, wall/floor finishes, and architectural products.

Target Audience in Cut Sheets (e.g., architects, contractors, installers)

While cut sheets contain very technical information, they need to be accessible to a broad audience, including:

- Architects & Engineers – Who specify and select the exact products.

- Contractors & Subcontractors – Who purchase and install the products.

- Suppliers & Distributors – Who provide and deliver the products.

- Building Owners – Who want to understand the product details.

- Facility Managers – Who will maintain the products long-term.

So cut sheets must strike a balance between technical specs and ease of comprehension.

Components of a Cut Sheet

General Details (applicable to most cut sheets)

Most cut sheets, regardless of product type, contain some general information:

- Manufacturer name and contact info

- Specific product model number(s)

- Date of publication

- Header with product name and image

Product Specifications (model number, manufacturer)

After general details, cut sheets dive into the specific product specifications:

- Dimensions, measurements, weights, and volumes

- Materials, finishes, and coatings

- Capacities, ratings, and tolerances

- Operating parameters like voltage, wattage, or flow rates

- Applicable testing and certification data

- Available options, accessories, and modifications

Materials and Measurements (dimensions, weight)

Exact materials and measurements are provided, covering details like:

- Product dimensions and size options

- Weight, for structural design and shipping considerations

- Materials used for each component

- Finishes and coatings for durability and aesthetics

Specific Details (depending on product category)

The product specifications get more granular based on the system type:

Electrical Cut Sheets

- Voltage, amperage, and wattage ratings

- Wiring diagrams and connection points

- Integration with lighting controls

- Energy efficiency and emissivity

Plumbing Cut Sheets

- Pipe sizes and pressure ratings

- Flow rates and temperature ranges

- Valve types and connections

- Compliance with plumbing codes

Structural Steel Cut Sheets

- Steel grade, yield strength, and composition

- Standard beam sizes and lengths

- Load and stress limits

- Fireproofing and corrosion protection

…(and so on for other product types)

Additional Information (may be included)

Cut sheets often contain supplemental information like:

- Installation guidelines – Step-by-step instructions and tolerances.

- Warranty details – Terms, conditions, and length of coverage.

- Sustainability credentials – Recycled content, LEED contributions, etc.

- Maintenance requirements – Cleaning processes, consumables, and schedules.

- Regulatory compliance – Building codes, testing standards, emissions, etc.

Creating an Effective Cut Sheet

To maximize the usefulness of cut sheets, here are some key considerations:

Clear and Concise Information

Cut sheets must distill technical complexity into clear, accessible language and easy-to-scan formats. Use bullet points, tables, charts, and diagrams wherever possible.

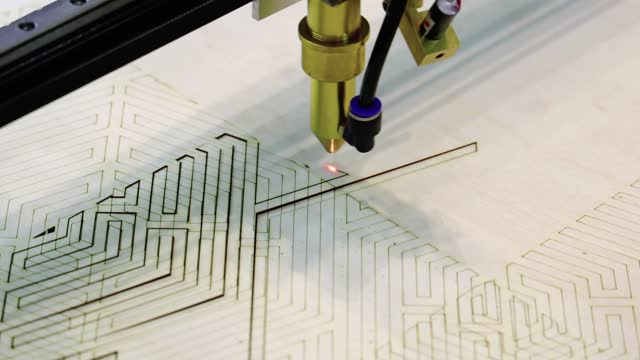

Visual Aids (diagrams, charts, images)

Including images, exploded views, schematics, and illustrations enhances understanding of the product and how it’s assembled or installed.

Technical Language (balanced with audience understanding)

A certain level of technical language is required for precision, but should be balanced with explanations of key terms so all stakeholders can follow along.

Standardizing Cut Sheet Formats

Consistent organization and styles improve comprehension and allow users to quickly locate the most important details.

Importance of Cut Sheets in Construction

Cut sheets provide invaluable benefits throughout the construction process:

Communication and Clarity (across project stakeholders)

Serving as a “single source of truth” for product data, cut sheets reduce miscommunications between architects, vendors, contractors, and building owners.

Error Reduction (ensuring accurate product selection and installation)

With all the necessary details in one place, the right products get ordered, delivered, and installed correctly.

Time and Cost Efficiency (streamlining procurement and construction)

Accurate cut sheets prevent delays from ordering wrong materials or products not fitting together properly.

Streamlining Procurement (ensuring all parties are on the same page regarding product specifications)

Cut sheets make the purchasing process smooth by providing contractors and suppliers with the exact product details needed.

Cut Sheets vs. Blueprints: Understanding the Difference

Cut sheets show the specifications for individual products, while blueprints show how everything fits together in the overall building design. Blueprints indicate the locations, sizes, and layout of architectural elements along with electrical, plumbing, and HVAC systems. Cut sheets offer the deeper dive into the technical attributes of each specific product selected. The two documents complement each other in creating a coordinated construction plan.

Utilizing Technology for Enhanced Cut Sheets

Building Information Modeling (BIM)

BIM software allows creating digital cut sheets tied directly to 3D building models, with real-time updates whenever changes are made. This enhances accuracy and connectivity.

Digital Cut Sheets (benefits: accessibility, real-time updates, integration with project management software)

Maintaining cut sheets in digital formats makes them easier to access, update, and integrate with other construction management systems for optimized workflow.

Using Cut Sheets in Different Phases of Construction

Design Phase

During design, architects specify products and compile cut sheets to communicate selections to clients and engineers. The cut sheets help turn broad design concepts into discrete construction requirements.

Procurement Phase

In procurement, contractors use cut sheets to properly order and purchase the approved products, avoiding incorrect substitutions down the line.

Construction Phase

During construction, cut sheets serve as official installation instructions that workers and inspectors can reference on-site to ensure quality and conformity with specifications.

Integration with Other Construction Documents

Cut sheets are most useful when cross-referenced with other documents like:

Blueprints – Cut sheets provide the specs for products located and dimensioned on plans.

Submittals – Cut sheets are packaged into official submittals for engineer approval.

Specifications – Cut sheets offer details left vague in the master specifications.

RFIs – Cut sheets clarify product questions raised in requests for information.

This interconnectivity ensures overall project coherence.

Legality and Regulations (brief mention)

Cut sheets may require certain information to show compliance with building codes and regulations, which can vary regionally. For example, ENERGY STAR ratings for lighting or UL listings for electrical.

Common Challenges and How to Overcome Them

Misinterpretation of Information

Complex cut sheets can lead to misinterpretation. Simplifying language, adding visual aids, and highlighting key bits help avoid this.

Inadequate Updates

Outdated cut sheets cause confusion. Digital formats make real-time updating easier.

Lack of Standardization

Inconsistent cut sheets formats lead to miscommunication. Standard templates fix this.

Examples of Cut Sheets in Construction

Electrical – Cut sheet for a light fixture, including voltage, lumens, optics, dimensions, and mounting options.

Plumbing – Cut sheet for a tankless water heater, showing activation flow rate, temperature rise, connectors, and energy factor.

Structural – Cut sheet for a steel I-beam, specifying material grade, section dimensions, weight, and fireproofing rating.

Architectural – Cut sheet for an aluminum storefront window system, listing sizes, glass properties, hardware, and thermal performance.

Conclusion

Cut sheets provide essential technical product information to all project stakeholders in the construction field. They promote clarity in communication, reduce errors, and streamline many processes when utilized correctly. As building practices evolve, cut sheets continue adapting through digitization and integration with other digital tools. Improving cut sheet utility via formatting, visuals, and interoperability remains an important pursuit.

Trayce served as a grassroots leader and activist in Texas as President of Dallas and Texas Eagle Forum.

Trayce is Mom Caucus Member, Texas Conservative Mamas, Texas Conservative Grassroots Coalition Leader, and Grassroots America Champion of Freedom Honoree.

She currently serves as the Eagle Forum National Issues Chair on Human Trafficking.

Trayce received a Bachelor’s Degree in Marketing from Texas A&M

Currently, she homeschools her youngest child age 13 and graduated her six oldest children, ages 31 to 19.